DTCV – electronic differential temperature control

| Codice / Code | Connessione / Connection | DN | PN | KVs | Portata min ÷ max/ Min ÷ max flow rarte | Δp |

|---|---|---|---|---|---|---|

| 230V 50/60Hz | ||||||

| DTCV2215_ | G1/2"B | 15 | 8* | 1.2 | 0,05 ÷ 0,9 m3/h | 3.4 |

| DTCV2220_ | G3/4"B | 20 | 8* | 2.8 | 0,11 ÷ 1,9 m3/h | 3.4 |

| DTCV2225_ | G1"B | 25 | 8* | 4.7 | 0,21 ÷ 3,0 m3/h | 3.4 |

| DTCV2232_ | G1"1/4B | 32 | 8* | 7.7 | 0,30 ÷ 5,1 m3/h | 3.4 |

| DTCV2240_ | G1"1/2B | 40 | 8* | 12.4 | 0,54 ÷ 9,0 m3/h | 3.4 |

| REGULATOR CALIBRATION | ||||||

| _ _ _ _ _ _ _ _ _ A | Radiators | |||||

| _ _ _ _ _ _ _ _ _ B | Radiant panels | |||||

| _ _ _ _ _ _ _ _ _ C | Fan coil | |||||

| * PN16 version available on request | ||||||

| 24V 50/60Hz | ||||||

| DTCV2415_ | G1/2"B | 15 | 8* | 1.2 | 0,05 ÷ 0,9 m3/h | 3.4 |

| DTCV2420_ | G3/4"B | 20 | 8* | 2.8 | 0,11 ÷ 1,9 m3/h | 3.4 |

| DTCV2425_ | G1"B | 25 | 8* | 4.7 | 0,21 ÷ 3,0 m3/h | 3.4 |

| DTCV2432_ | G1"1/4B | 32 | 8* | 7.7 | 0,30 ÷ 5,1 m3/h | 3.4 |

| DTCV2440_ | G1"1/2B | 40 | 8* | 12.4 | 0,54 ÷ 9,0 m3/h | 3.4 |

| REGULATOR CALIBRATION | ||||||

| _ _ _ _ _ _ _ _ _ A | Radiators | |||||

| _ _ _ _ _ _ _ _ _ B | Radiant panels | |||||

| _ _ _ _ _ _ _ _ _ C | Fan coil | |||||

| * PN16 version available on request | ||||||

| COIBENTAZIONE / INSULATION | ||||||

| Codice / Code | DN | |||||

| CBCV15 | 15 | |||||

| CBCV20 | 20 | |||||

| CBCV25 | 25 | |||||

| CBCV32 | 32 | |||||

| CBCV40 | 40 |

FEATURES AND FUNCTIONS

• Pressure-independent flow rate control

• Δt ontrol with flow rate limitation

• Δt control with power limitation

• Energy Monitoring

• 2-way regulating ball valve with equal percentage profile

• Shut-off function

• Contact temperature sensors

• Flow sensor with Vortex technology

• Integrated monitoring and control interface

• Analog inputs and digital outputs

• Modbus-RTU remote management

ePICV – electronic flow control

| Codice / Code | Connessione / Connection | DN | PN | KVs | Portata min ÷ max/ Min ÷ max flow rarte | Δp |

|---|---|---|---|---|---|---|

| 230V 50/60Hz | ||||||

| EPICV2215 | G1/2"B | 15 | 8* | 1.2 | 0,05 ÷ 0,9 m3/h | 3.4 |

| EPICV2220 | G3/4"B | 20 | 8* | 2.8 | 0,11 ÷ 1,9 m3/h | 3.4 |

| EPICV2225 | G1"B | 25 | 8* | 4.7 | 0,21 ÷ 3,0 m3/h | 3.4 |

| EPICV2232 | G1"1/4B | 32 | 8* | 7.7 | 0,3 ÷ 5,1 m3/h | 3.4 |

| EPICV2240 | G1"1/2B | 40 | 8* | 12.4 | 0,54 ÷ 9,0 m3/h | 3.4 |

| 24V 50/60Hz | ||||||

| EPICV2415 | G1/2"B | 15 | 8* | 1.2 | 0,05 ÷ 0,9 m3/h | 3.4 |

| EPICV2420 | G3/4"B | 20 | 8* | 2.8 | 0,11 ÷ 1,9 m3/h | 3.4 |

| EPICV2425 | G1"B | 25 | 8* | 4.7 | 0,21 ÷ 3,0 m3/h | 3.4 |

| EPICV2432 | G1"1/4B | 32 | 8* | 7.7 | 0,3 ÷ 5,1 m3/h | 3.4 |

| EPICV2440 | G1"1/2B | 40 | 8* | 12.4 | 0,54 ÷ 9,0 m3/h | 3.4 |

| * PN16 version available on request | ||||||

| COIBENTAZIONE / INSULATION | ||||||

| Codice / Code | DN | |||||

| CBCV15 | 15 | |||||

| CBCV20 | 20 | |||||

| CBCV25 | 25 | |||||

| CBCV32 | 32 | |||||

| CBCV40 | 40 |

FEATURES AND FUNCTIONS

• Pressure-independent flow rate control

• 2-way regulating ball valve with equal percentage profile

• Shut-off function

• Flow sensor with Vortex technology

• Integrated control panel and datalogger function

• Analogue signal 0-10V for flow rate setpoint

• Modbus-RTU remote management

eRTCV – electronic return temperature control

| Codice / Code | Connessione / Connection | DN | PN | Portata max/ max flow rarte | Δp |

|---|---|---|---|---|---|

| 230V 50/60Hz | |||||

| ERTCV2215A_ | 1/2" | 15 | 25 | 0.36 m3/h | 6 |

| ERTCV2215B_ | 1/2" | 15 | 25 | 0.70 m3/h | 6 |

| ERTCV2215C_ | 1/2" | 15 | 25 | 1.00 m3/h | 6 |

| ERTCV2220A_ | 3/4" | 20 | 25 | 0.78 m3/h | 6 |

| ERTCV2220B_ | 3/4" | 20 | 25 | 1.15 m3/h | 6 |

| ERTCV2225A_ | 1" | 25 | 25 | 2.20 m3/h | 6 |

| ERTCV2225B_ | 1" | 25 | 25 | 2.70 m3/h | 6 |

| ERTCV2225C_ | 1"1/4 | 25 | 25 | 3.00 m3/h | 6 |

| ERTCV2225D_ | 1"1/4 | 25 | 25 | 4.00 m3/h | 6 |

| ERTCV2240A_ | 1"1/2 | 40 | 16 | 6.00 m3/h | 6 |

| ERTCV2240B_ | 1"1/2 | 40 | 16 | 9.00 m3/h | 6 |

| ERTCV2250A_ | 2" | 50 | 16 | 12.00 m3/h | 6 |

| ERTCV2250B_ | 2" | 50 | 16 | 18.00 m3/h | 6 |

| REGULATOR CALIBRATION | |||||

| _ _ _ _ _ _ _ _ _ A | Radiators | ||||

| _ _ _ _ _ _ _ _ _ B | Radiant panels | ||||

| _ _ _ _ _ _ _ _ _ C | Fan coil | ||||

| 24V 50/60Hz | |||||

| ERTCV2215A | 1/2" | 15 | 25 | 0.36 m3/h | 6 |

| ERTCV2215B | 1/2" | 15 | 25 | 0.70 m3/h | 6 |

| ERTCV2215C | 1/2" | 15 | 25 | 1.00 m3/h | 6 |

| ERTCV2220A | 3/4" | 20 | 25 | 0.78 m3/h | 6 |

| ERTCV2220B | 3/4" | 20 | 25 | 1.15 m3/h | 6 |

| ERTCV2225A | 1" | 25 | 25 | 2.20 m3/h | 6 |

| ERTCV2225B | 1" | 25 | 25 | 2.70 m3/h | 6 |

| ERTCV2225C | 1"1/4 | 25 | 25 | 3.00 m3/h | 6 |

| ERTCV2225D | 1"1/4 | 25 | 25 | 4.00 m3/h | 6 |

| ERTCV2240A | 1"1/2 | 40 | 16 | 6.00 m3/h | 6 |

| ERTCV2240B | 1"1/2 | 40 | 16 | 9.00 m3/h | 6 |

| ERTCV2250A | 2" | 50 | 16 | 12.00 m3/h | 6 |

| ERTCV2250B | 2" | 50 | 16 | 18.00 m3/h | 6 |

| REGULATOR CALIBRATION | |||||

| _ _ _ _ _ _ _ _ _ A | Radiators | ||||

| _ _ _ _ _ _ _ _ _ B | Radiant panels | ||||

| _ _ _ _ _ _ _ _ _ C | Fan coil | ||||

| COIBENTAZIONE / INSULATION | |||||

| Codice / Code | Connessione / Connection | ||||

| CBCV15R | 1/2" | ||||

| CBCV20R | 3/4" | ||||

| CBCV25R | 1" | ||||

| CBCV32R | 1"1/4 | ||||

| CBCV40R | 1"1/2 | ||||

| CBCV50R | 2" |

FEATURES AND FUNCTIONS

• Pressure-independent flow rate control

• Return temperature control for heating and/or cooling systems

• Shut-off function

• Contact temperature sensors

• Integrated control panel and datalogger function

• Analogue signal 0-10V for flow rate setpoint

• Modbus-RTU remote management

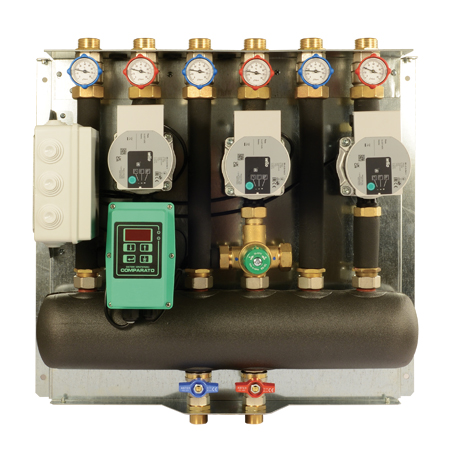

COMPACT SYSTEM

| Creazione codice tramite CODE BUILDER / Code creation via CODE BUILDER | es: SK30MHD |

|---|---|

| Lamiera pensile / Wall-hanging sheet metal box | |

| 2 zone 2 zones | SK2 |

| 3 zone 3 zones | SK3 |

| Funzione/ Function | |

| Riscaldamento/ Heating | O |

| Riscaldamento e raffrescamento/ Heating and cooling | R |

| Tipologia zona sinistra / Zone type - left | |

| Gruppo diretto Direst unit | D |

| Gruppo miscelato a punto fisso 30°C - 60°C Mixing fixed-point unit 30°C - 60°C | H |

| Gruppo miscelato modulante con elettronica integrata per pannelli radianti Mixing modulating unit with on-board electronics for radiant panels | M |

| Tipologia zona centrale / Zone type - central | |

| Gruppo diretto Direst unit | D |

| Gruppo miscelato a punto fisso 30°C - 60°C Mixing fixed-point unit 30°C - 60°C | H |

| Gruppo miscelato modulante con elettronica integrata per pannelli radianti Mixing modulating unit with on-board electronics for radiant panels | M |

| Tipologia zona destra / Zone type - right | |

| Non presente - sottostazione a 2 zone Not present - 2-zone understation | O |

| Gruppo diretto Direst unit | D |

| Gruppo miscelato a punto fisso 30°C - 60°C Mixing fixed-point unit 30°C - 60°C | H |

| Gruppo miscelato modulante con elettronica integrata per pannelli radianti Mixing modulating unit with on-board electronics for radiant panels | M |

SYSTEM OF ZONE PLANT MANAGEMENT

3-ZONE MANIFOLD WITH INTEGRATED HYDRAULIC SEPARATOR

DIRECT ZONE, MIXING FIXED-POINT ZONE AND MIXING MODULATING ZONE WITH WEATHER COMPENSATION REGULATION

POWER SUPPLY 230V 50Hz

DIATECH PDC

| Product Type | Model |

|---|---|

| Hydraulic interface unit for heating and DHW production with increased heat exchanger for systems with heat pump | Diatech PDC |

| COMPONENTS | |

| Strainer | |

| Manual interception valves (version with template box) | |

| DHW temperature probe | |

| Flowmeter | |

| Flow static limiter | |

| Heat exchanger | |

| Diamant 2000 2-way modulating motorised valve on sanitary circuit | |

| Sintesi 2-way ON/OFF motorised valve on primary circuit | |

| Electronics management box | |

| Energy meter, M-Bus reading / Ultrasonic energy meter | |

| Sanitary water meter, M-Bus reading | |

| Treated and/or pre-heated sanitary water meter, M-Bus reading | Optional |

| Template box (recessed installation) | Optional |

| White casing (wall hanging) | Optional |

| Plant balancing with static balancing valve / Plant balancing with DPCV / Plant balancing with Modflow - electronic flow control | Optional |

| Non-return valve | Optional |

| System start-up and technical support | Optional |

Direct energy metering

Centralised heating plant management

Plated heat exchanger for DHW production

Hot and cold sanitary water lines

For heating plant with heat pump

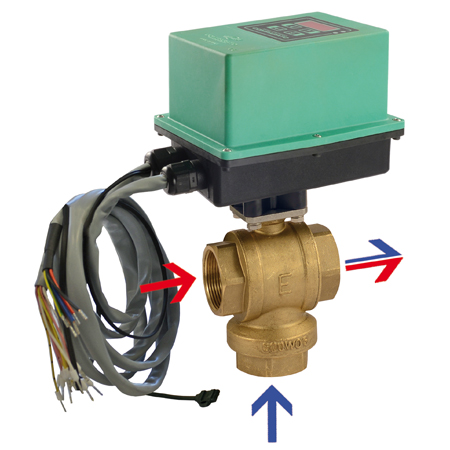

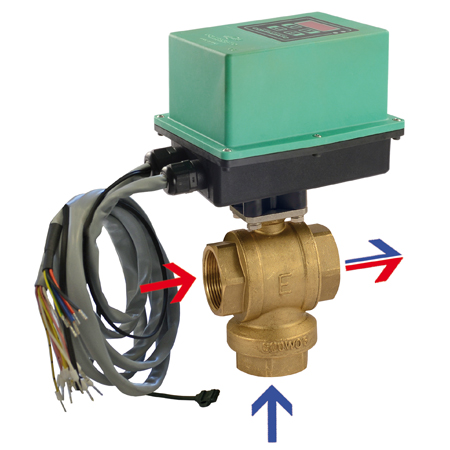

Clima diverting motorised valve – MMM connections

| Codice / Code | Tensione / P. supply | Connessione / Connection | DN | KVs | PN | ΔP |

|---|---|---|---|---|---|---|

| CLIMAPCDCB | 230 V 50/60 Hz | 3/4" | 20 | 11,5 | 16 | 16 bar |

| CLIMAPCDCC | 230 V 50/60 Hz | 1" | 25 | 18,3 | 16 | 16 bar |

HEATING PLANTS WITH HEAT PUMP

Diverting valve for automatic switching between heat pump and boiler:

- Automatic switching between HP and boiler according to outdoor temperature

- Control of the diverting valve to the DHW heater

- Data storage of the working time of HP and boiler

IP65 class protection

3-way brass ball valve, full bore, MMM PN 16

Modbus-RTU protocol for remote management

Diamant PRO actuator – WINEMAKING

| Codice / Code | Per corpo valvola / For ball valve | V | Frequenza / Frequency | Coppia / Torque | Tempi di manovra / Operating times | Angolo ° / Angle ° |

|---|---|---|---|---|---|---|

| DY242P2R | 2 - 3 VIE / WAY | 24V | 50/60 Hz | 11 Nm | 35 sec | 90° |

| DY342P2R | 3 VIE / WAY | 24V | 50/60 Hz | 11 Nm | 70 sec | 180° |

USE: WINEMAKING INDUSTRY

Torque: 11 Nm

ALL-IN-ONE actuator for 3 points without relay or 2 points with relay connection

Class protection: IP67

Operating time: 35 sec for 90° rotation

2 extra micro-switches

Internal heating resistance

DIAMIX PR motorised valve – vertical in line mixed outlet

| Codice / Code | Tensione / P. supply | Connessione / Connection | DN | KVs | PN | ΔP |

|---|---|---|---|---|---|---|

| DIAMIXPFBPRV | 230 V 50/60 Hz | 3/4" MMM | 20 | 6,7 | 16 | 3,5 bar |

| DIAMIXPFCPRV | 230 V 50/60 Hz | 1" MMM | 25 | 11,4 | 16 | 3,5 bar |

| DIAMIXPFDPRV | 230 V 50/60 Hz | 1"1/4 MMM | 32 | 17,5 | 16 | 3,5 bar |

| DIAMIXPFEPRV | 230 V 50/60 Hz | 1"1/2 FFF | 40 | 26,8 | 16 | 3,5 bar |

| DIAMIXPFFPRV | 230 V 50/60 Hz | 2" FFF | 50 | 52,6 | 16 | 3,5 bar |

Thermal regulation in UNDERFLOOR SYSTEMS

Mixing thermoregulating actuator with electronics onboard

Temperature control:

- Fixed-point or climatic HEATING

- Fixed-point or dew-point temperature trackingt COOLING

Summer winter switching

Semiconductor temperature sensor

Class protection IP65

3-way BRASS ball valve, PN16

Remote management with Modbus-RTU protocol

DIAMIX PLUS motorised valve – vertical in line mixed outlet

| Codice / Code | Tensione / P. supply | Connessione / Connection | DN | KVs | PN | ΔP |

|---|---|---|---|---|---|---|

| DIAMIXPFBV | 230 V 50/60 Hz | 3/4" MMM | 20 | 6,7 | 16 | 3,5 bar |

| DIAMIXPFCV | 230 V 50/60 Hz | 1" MMM | 25 | 11,4 | 16 | 3,5 bar |

| DIAMIXPFDV | 230 V 50/60 Hz | 1"1/4 MMM | 32 | 17,5 | 16 | 3,5 bar |

| DIAMIXPFEV | 230 V 50/60 Hz | 1"1/2 FFF | 40 | 26,8 | 16 | 3,5 bar |

| DIAMIXPFFV | 230 V 50/60 Hz | 2" FFF | 50 | 52,6 | 16 | 3,5 bar |

HEATING / REGULATION IN GENERAL

Mixing thermoregulating actuator with electronics onboard

Temperature control:

- fixed-point

- climatic function for high/medium temperature systems

- temperature set-point with 0-10V remote signal

Semiconductor temperature sensor

Class protection IP65

3-way BRASS ball valve, PN16

Remote management with Modbus-RTU protocol

Magnetic Filter

| Codice / Code | Attacchi / Connections | Corpo / Body | Grado di Filtrazione / Degree of Filtration |

|---|---|---|---|

| Filettati / Threaded | |||

| FT001 | Ø 1" | 4" | 900 μm |

| FT114 | Ø 1"1/4 | 4" | 900 μm |

| FT112 | Ø 1"1/2 | 5" | 900 μm |

| FT002 | Ø 2" | 5" | 900 μm |

| Flangiati PN 10-16 / Flanged PN 10-16 | |||

| FT212 | DN 65 | 8" | 900 μm |

| FT003 | DN 80 | 8" | 900 μm |

| FT004 | DN 100 | 10" | 900 μm |

DIAFIL is the filter for heating plant for the prevention of circulators and other system components.

Provided with magnet and manual drain for periodic cleaning.

It can measure the differential pressure thanks to its threaded connections.

COMPACT PRO actuator – IP68 (waterproof)

| Codice / Code | Per corpo valvola / For ball valve | V | Frequenza / Frequency | Coppia / Torque | Tempi di manovra / Operating times | Angolo ° / Angle ° |

|---|---|---|---|---|---|---|

| CH2222P | 2 - 3 VIE / WAY | 230V | 50/60 Hz | 22 Nm | 45 sec | 90° |

| CH2122P | 2 - 3 VIE / WAY | 110V | 50/60 Hz | 22 Nm | 45 sec | 90° |

| CH2422P | 2 - 3 VIE / WAY | 24V | 50/60 Hz | 22 Nm | 45 sec | 90° |

| CH3222P | 3 VIE / WAY | 230V | 50/60 Hz | 22 Nm | 90 sec | 180° |

| CH3122P | 3 VIE / WAY | 110V | 50/60 Hz | 22 Nm | 90 sec | 180° |

| CH3422P | 3 VIE / WAY | 24V | 50/60 Hz | 22 Nm | 90 sec | 180° |

INDUSTRIAL USE

ALL-IN-ONE actuator for 3 points without relay or 2 points with relay connection

Class protection: IP68 – total immersion for industrial use

Operating time: 45 sec for 90° rotation – 22Nm

Diamant Smart PRO

| Creazione codice tramite CODE BUILDER / Code creation via CODE BUILDER | es: DSP24CWFA |

|---|---|

| Diamant Smart PRO | DSP |

| Angolo di rotazione / Rotation angle | |

| 90° | 2 |

| 180° | 3 |

| Alimentazione elettrica / Power supply | |

| 100... 240V 50/60Hz | 2 |

| 12-24V AC/DC | 4 |

| Connessione al corpo valvola / Connection to the ball valve | |

| Comparato | C |

| ISO 5211 F03-F05 Q 9-11 | F |

| Tipo di comunicazione / Communication type | |

| Modbus | M |

| Wi-Fi | W |

| Fail Safe | |

| Presente / Present | F |

| Assente / Not present | O |

| Apertura manuale di emergenza / Emergency Manual Opening | |

| Presente / Present | A |

USE: INDUSTRIAL PLANTS, AUTOMATION SYSTEMS, HEATING / COOLING AND SANITARY WATER

TORQUE: 11 Nm

POSITIONING FEEDBACK 2-10V

TWO EXTRA MICRO SWITCHES

COMMUNICATION VIA WI-FI OR MODBUS-RTU

INGRESS PROTECTION: IP67

MANUAL OPENING

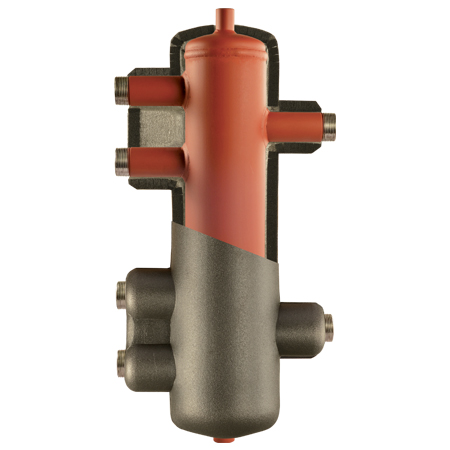

DIACOM hydraulic separator

| Codice / Code | Attacchi / Connections | Corpo / Body | Portate Indicative / Approximate Flow Rates | Volume / Volume |

|---|---|---|---|---|

| Filettati / Threaded | ||||

| C001 | Ø 1" | 3" | 2 m³/h * | 2.2 l |

| C114 | Ø 1"1/4 | 4" | 3.5 m³/h * | 5 l |

| C112 | Ø 1"1/2 | 4" | 5 m³/h * | 6 l |

| C002 | Ø 2" | 5" | 8 m³/h * | 12 l |

| Flangiati PN 10-16 / Flanged PN 10-16 | ||||

| C212 | DN 65 | 6" | 12 m³/h * | 21 l |

| C003 | DN 80 | 8" | 18 m³/h * | 42 l |

| C004 | DN 100 | 10" | 30 m³/h * | 84 l |

| C005 | DN 125 | 12" | 50 m³/h * | 146 l |

| C006 | DN 150 | 16" | 70 m³/h * | 260 l |

| C008 | DN 200 | 20" | 120 m³/h * | 548 l |

| C010 ** | DN 250 | 800 mm | 150 m³/h * | - |

| C012 ** | DN 300 | 950 mm | 220 m³/h * | - |

| COIBENTAZIONE INSULATION | ||||

| CBC001 | Ø 1" | |||

| CBC114 | Ø 1"1/4 | |||

| CBC112 | Ø 1"1/2 | |||

| CBC002 | Ø 2" | |||

| CBC212 | DN 65 | |||

| CBC003 | DN 80 | |||

| CBC004 | DN 100 | |||

| * Con una perdita di carico di 100 daPa With a load loss of 100 daPa | ||||

| ** Attacchi coassiali Coaxial connection |

Hydraulic compensator with additional functions of air and deposit separator for heating plants

Carbon steel

Insulation

Out-of-standard products can be realised according to Customer’s requirements

DIADIS HYDRAULIC SEPARATOR

3 INDEPENDENT CIRCUITS

| Codice / Code | Attacchi / Connections | Corpo / Body | Portate Indicative / Approximate Flow Rates | Volume / Volume |

|---|---|---|---|---|

| Filettati / Threaded | ||||

| T001 | Ø 1" | 3" | 2 m³/h * | 2.2 l |

| T114 | Ø 1"1/4 | 4" | 3.5 m³/h * | 5 l |

| T112 | Ø 1"1/2 | 4" | 5 m³/h * | 6 l |

| T002 | Ø 2" | 5" | 8 m³/h * | 12 l |

| COIBENTAZIONE INSULATION | ||||

| CBT001 | Ø 1" | |||

| CBT114 | Ø 1"1/4 | |||

| CBT112 | Ø 1"1/2 | |||

| CBT002 | Ø 2" | |||

| * Con una perdita di carico di 100 daPa With a load loss of 100 daPa |

Hydraulic separator for 3 independent hydraulic circuits

With additional functions of air and deposit separator for heating plants

Carbon steel

Insulation

Out-of-standard products can be realised according to Customer’s requirements

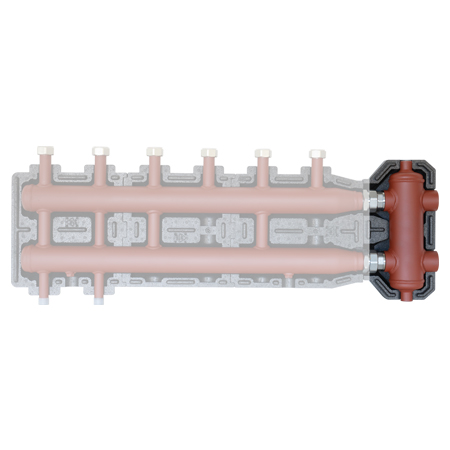

Manifolds with integrated hydraulic compensator: DIASYS

| Codice / Code | Zone / Zones | Attacchi Principali / Main Connections | Attacchi Derivazioni / Outlet Connections | i |

|---|---|---|---|---|

| COLLETTORE MANIFOLD | ||||

| CCI0234GR | 2 | 1"1/4 | G 1" | 125 mm |

| CCI0334GR | 3 | 1"1/4 | G 1" | 125 mm |

| CCI3134GR | 3+1 * | 1"1/4 | G 1" | 125 mm |

| CCI3234GR | 3+2 * | 1"1/4 | G 1" | 125 mm |

| COIBENTAZIONE INSULATION | ||||

| CBCCI0234 | 2 | 1"1/4 | G 1" | 125 mm |

| CBCCI0334 | 3 | 1"1/4 | G 1" | 125 mm |

| CBCCI3134 | 3+1 * | 1"1/4 | G 1" | 125 mm |

| CBCCI3234 | 3+2 * | 1"1/4 | G 1" | 125 mm |

125 interaxis manifold for pump unit with integrated hydraulic compensator with nut outlet

Carbon steel

Insulation

Fixing kit

Out-of-standard products can be realised according to Customer’s requirements

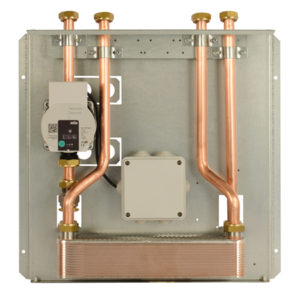

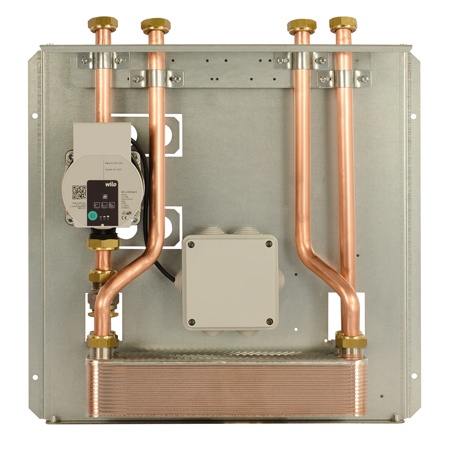

ECOKAM T

| Codice / Code | Potenza caldaia a gas / Max source power | Circolatori / Pumps |

|---|---|---|

| ES1P24E | 24 kW | 1 |

| ES1P35E | 35 kW | 1 |

Heating interface unit

Dedicated to hot water production for heating

Hydraulical separation of the fireplace circuit (without expansion vessel) and the boiler circuit (with expansion vessel)

With plated heat exchanger for heating dimensioned according to the boiler’s power

For connection to distribution manifold

SINTESI ALL-IN-ONE motorised valve – 2-way MM BRASS

| Codice / Code | V | Misura / Size | DN | PN | KVS | Tempi di manovra / Operating times |

|---|---|---|---|---|---|---|

| SY2221A2AB | 230 V 50/60 Hz | 1/2" | 15 | 16 | 16,3 | 45 sec (90°) |

| SY2221B2AB | 230 V 50/60 Hz | 3/4" | 20 | 16 | 29,5 | 45 sec (90°) |

| SY2221C2AB | 230 V 50/60 Hz | 1" | 25 | 16 | 43 | 45 sec (90°) |

HEATING / COOLING / SANITARY WATER

ON-OFF and modulating functioning, with 1 extra free micro switch on opening

2-3 points control actuator with relay

Class protection: IP54

Operating time: 35 sec for 90° rotation

2-way MM BRASS ball valve with tangs, full bore

Fast push connection

3 way FFF BRASS Sintesi ball valve – EQUAL PERCENTAGE

| Codice / Code | Connessione / Connection | DN | Δp max | KVS |

|---|---|---|---|---|

| SC3ARKVA | 1/2" | 15 | 3,4 bar | 0,25 |

| SC3ARKVB | 1/2" | 15 | 3,4 bar | 0,4 |

| SC3ARKVC | 1/2" | 15 | 3,4 bar | 0,63 |

| SC3ARKVD | 1/2" | 15 | 3,4 bar | 1 |

| SC3ARKVE | 1/2" | 15 | 3,4 bar | 1,6 |

| SC3ARKVF | 1/2" | 15 | 3,4 bar | 2,5 |

| SC3ARKVG | 1/2" | 15 | 3,4 bar | 4 |

| SC3ARKVH | 1/2" | 15 | 3,4 bar | 6,3 |

| SC3BRKVG | 3/4" | 20 | 3,4 bar | 4 |

| SC3BRKVH | 3/4" | 20 | 3,4 bar | 6,3 |

| SC3BRKVJ | 3/4" | 20 | 3,4 bar | 10 |

| SC3CRKVH | 1" | 25 | 3,4 bar | 6,3 |

| SC3CRKVJ | 1" | 25 | 3,4 bar | 10 |

| SC3CRKVK | 1" | 25 | 3,4 bar | 16 |

| SC3DRKVJ | 1"1/4 | 32 | 3,4 bar | 10 |

| SC3DRKVK | 1"1/4 | 32 | 3,4 bar | 16 |

| SC3DRKVL | 1"1/4 | 32 | 3,4 bar | 25 |

| SC3ERKVK | 1"1/2 | 40 | 3,4 bar | 16 |

| SC3ERKVL | 1"1/2 | 40 | 3,4 bar | 25 |

| SC3FRKVL | 2" | 50 | 3,4 bar | 25 |

| SC3FRKVM | 2" | 50 | 3,4 bar | 25 |

3-way FFF BRASS

Equal percentage PN16

DIACOM MINI hydraulic separator

| Codice / Code | Attacchi / Connections | Tipo Attacco / Connection Type | Corpo / Body | Portate Indicative / Approximate Flow Rates | Volume / Volume |

|---|---|---|---|---|---|

| CM114 | 1"1/4 | filettato F threaded F | 2"1/2 | ||

| COIBENTAZIONE INSULATION | |||||

| CBCM114 | 1"1/4 | filettato F threaded F | 2"1/2 |

Compact hydraulic compensator

Carbon steel

Insulation

Out-of-standard products can be realised according to Customer’s requirements

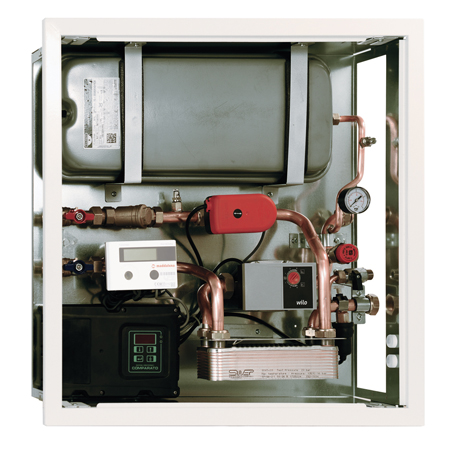

CONTER R

| Product Type | Model |

|---|---|

| Hydraulic interface unit for re-buildings | Conter R |

| COMPONENTS | |

| Strainer | |

| Inlet manual interception valves | |

| 2-way body valve | |

| Heat exchanger | |

| Pump | |

| Safety valve | |

| Manometer | |

| Safety thermostat | |

| Expansion vessel | |

| Filling point | |

| Electronics management box | |

| Wireless M-Bus heat meters | |

| Sintesi 2-way modulating actuator | |

| Flow temperature probe | |

| Mechanical energy meter, heating only, M-Bus / Ultrasonic energy meter, heating only, M-Bus / Mechanical energy meter, heating only, wireless M-Bus / Ultrasonic energy meter, heating only, wireless M-Bus | |

| Flow rate control with balancing valve | Optional |

| Distribution manifold with motorized valves / Distribution manifold with electromechanical heads | Optional |

| External probe for wheather compensation | Optional |

| System start-up and technical support | Optional |

The hydraulic interface unit for the re-buildings

Studied for the one who wants to replace the radiators with the radiant panels in centralized plants.

Recessed installation.

Complete of the whole material to manage the new plant to panels radiant plates.

Heat exchanger for the complete hydraulic separation.

ERP Ready pump.

Wireless M-Bus direct metering.

Surge chamber.

Safety valve.

Sintesi modulating motorised valve.

Electronics management file with digital display.

Temperature probe and safety thermostat.

Available also with distribution manifolds.